There are things that cannot be described in words. Like the aroma

of freshly ground coffee. Or the sensation evoked by a good design. It

is a moment, an instant, a feeling, sometimes incomprehensible.

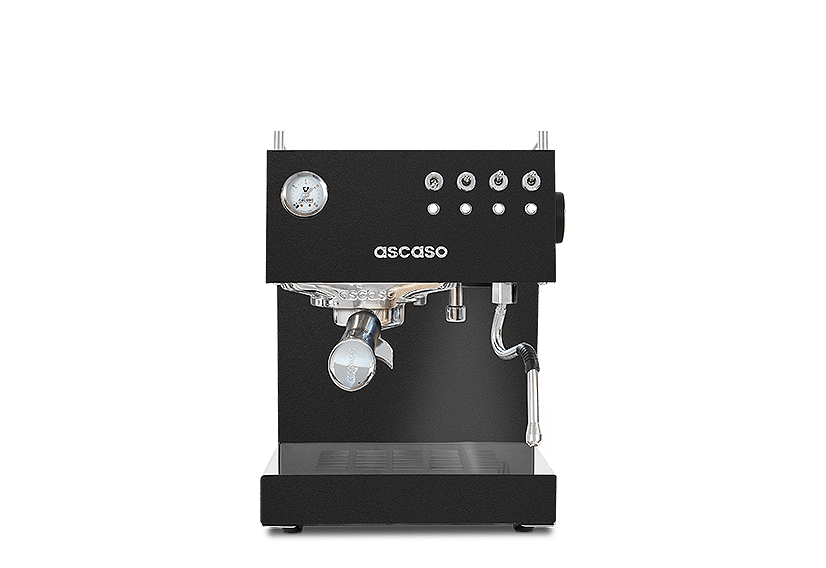

Professional Espresso Machines.

Home collection

Commercial collection

Grinders and accesories

A way of being, doing and inspiring.

DESIGN

Ideas that come together to create espresso machines that are innovative, reliable, and a joy to use—perfect for anyone passionate about the perfect cup of coffee.

TECHNOLOGIES

There is a secret ingredient in coffee, it's called technology. Our T technology provides the control, temperature stability, and efficiency needed for the highest cup quality.

SUSTAINABILITY

Our T-technology has revolutionized the energy efficiency of our coffee machines, offering solutions that significantly reduce energy consumption and provide substantial economic benefits.

BARISTA

Our coffee machines combine tradition and modernity, crafted specifically for coffee enthusiasts who appreciate the art and ritual of espresso making.

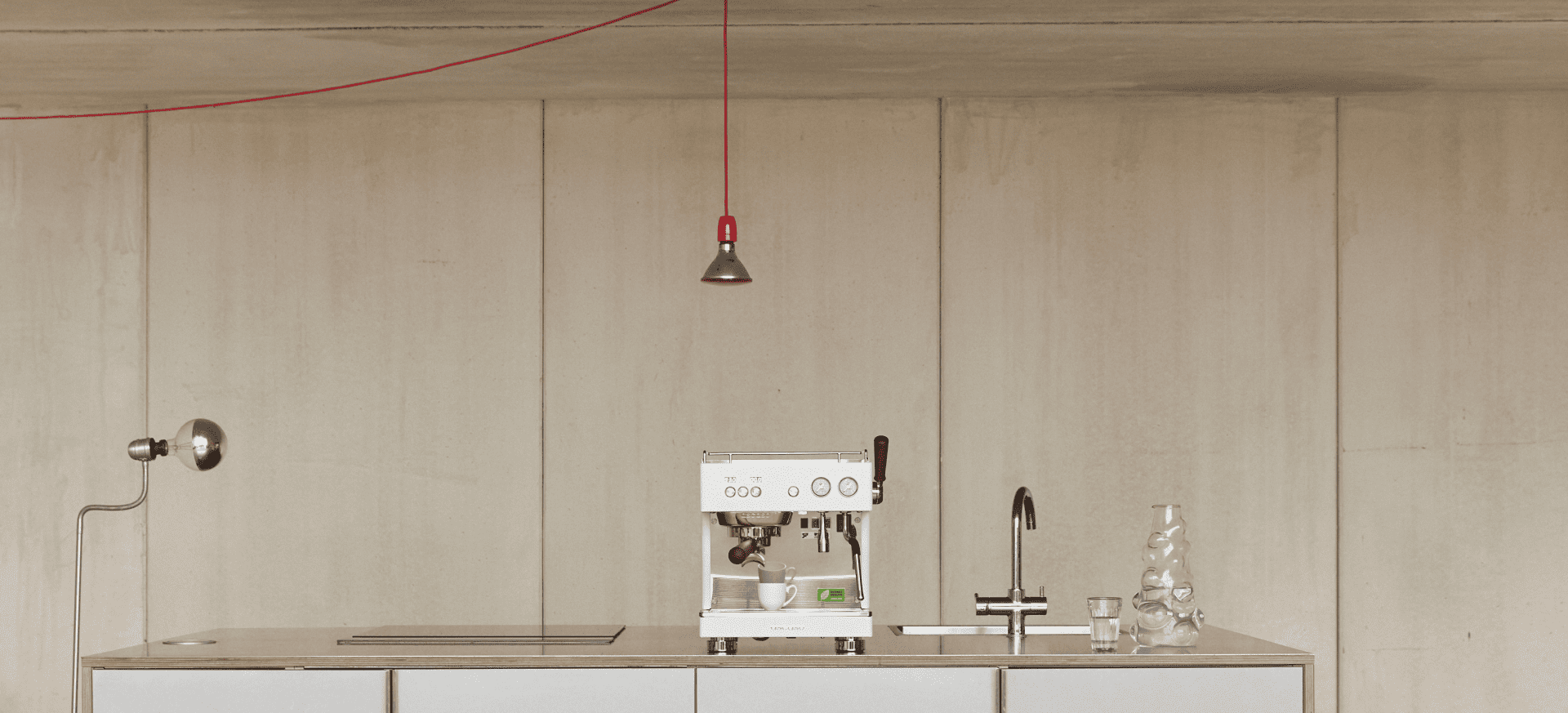

#AscasoCommunity

We love to see how Ascaso dresses any spaces, anywhere.

Share your spot with our community via Instagram with

@ascaso_official and #ForGenuinecoffeelovers

Follow us on linkedin aswell @ascaso